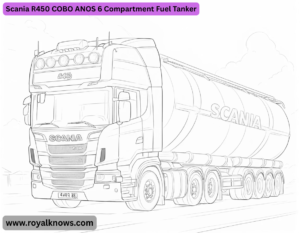

Scania R450 COBO ANOS 6 Compartment Fuel Tanker The Scania R450 COBO ANOS 6 Compartment Fuel Tanker is a specialized truck designed for the safe and efficient transportation of fuel. Below are its key features and specifications:

Chassis & Powertrain

- Manufacturer: Scania

- Model: R450

- Engine: DC13 147 (13L, 6-cylinder)

- Power Output: 450 HP

- Torque: 2350 Nm (at 1000-1300 rpm)

- Transmission: Scania Opti cruise (Automated Manual Transmission)

- Axle Configuration: Typically 4×2 or 6×2, depending on regional requirements

- Fuel Tank Capacity (Vehicle): ~600-800L (varies by configuration)

Tanker Specifications

- Tanker Type: Fuel tanker with 6 compartments (ANOS certification)

- Material: Aluminum or stainless steel (corrosion-resistant)

- Capacity: ~36,000–40,000 liters (varies by design & regulations)

- Compartments: 6 individually sealed sections for multi-product transport

- Pump System: Equipped with a high-flow pump (e.g., 500–1000 L/min)

- Metering System: Digital or mechanical gauges for accurate measurement

Safety Features:

- ANOS Certification (European standard for fuel tankers)

- Anti-spill valves

- Grounding system (static electricity prevention)

- Fire suppression system (optional)

- Rear underrun protection

Applications

- Diesel, gasoline, or Ad Blue transport

- Refueling stations, depots, and industrial sites

Additional Features

- COBO (Cab Over Engine) Design: Optimized for maneuverability

- Compliance: ADR (European dangerous goods regulations)

- Telematics: Scania Fleet Management System for tracking & efficiency

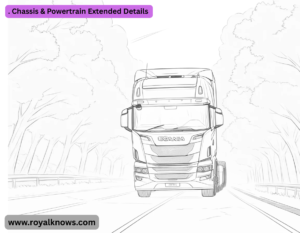

1. Chassis & Powertrain Extended Details

- Engine (DC13 147):

- Euro 6 compliant (or regional equivalent, e.g., Euro V/EEV)

- SCR (Selective Catalytic Reduction) + EGR for emissions control

- Fuel efficiency features: Scania’s Eco Roll (coasting function) & predictive cruise control

- Transmission:

- Scania Opti cruise (12-speed automated gearbox) with Retarder or Exhaust Brake

- Optional: Scania GRSO926R (manual 12-speed) for heavy-duty operations

- Axle Options:

- 4×2: Common for lighter loads (~26–36T GCW)

- 6×4: Full traction for off-site refueling (e.g., mining/construction)

2. Tanker Body (ANOS Compliance & Safety)

- ANOS Certification (EN 13012):

- Mandatory in Europe for fuel tankers (ensures leak-proof design, crash resistance, and fire safety).

- Requires:

- Double-skin construction (outer shell protects inner tank)

- Overfill prevention system (90% auto-shutoff)

- Bottom-loading valves (reduces vapor emissions vs. top-loading)

- Compartmentalization:

- Typical 6-compartment layout (e.g., 3x 6,000L + 3x 4,000L for varied fuel types).

- Baffles: Anti-surge plates to stabilize liquid movement.

- Pump & Metering:

- Pump Types:

- Rotary gear pump (500–1,200 L/min flow rate)

- Optional: ATEX-certified for explosive environments

- Meter Accuracy: ±0.5% (legal trade requirement in most countries).

3. Operational Features

- Safety Systems:

- Static Grounding: Cable + interlock system to prevent sparks during loading/unloading.

- Emergency Shutoff: Remote-operated valves (via cab or wireless pendant).

- Ventilation: Pressure/vacuum relief valves for vapor control.

- ADR Compliance (Transporting Dangerous Goods):

- Class 3 (Flammable Liquids) – Requires:

- Orange hazard placards

- Fire extinguishers (2x 6kg powder)

- Driver ADR training certification

- Telematics & Tracking:

- Scania Fleet Management (real-time fuel monitoring, route optimization, theft prevention).

4. Customization Options

- Material Choices:

- Aluminum: Lightweight (~300–400kg lighter than steel), corrosion-resistant.

- Stainless Steel: For aggressive fuels (e.g., biodiesel, ethanol blends).

- Add-ons:

- Heated compartments (for cold climates to prevent fuel gelling).

- Vapor recovery system (environmental compliance).

- Rear-mounted hose reel (for direct refueling of equipment).

- Cab Options:

- Highline Cab: Sleeper berth for long-haul operations.

- Day Cab: For regional/short-haul deliveries.

5. Typical Use Cases

- Petrol Stations: Multi-compartment loads (e.g., diesel + gasoline + kerosene).

- Aviation Fuel: Dedicated stainless steel tanks for Jet-A1 (requires additional certifications).

- Industrial Sites: Off-road fuel delivery to mining/farming operations.

6. Maintenance & Lifespan

- Service Intervals: Every 60,000–90,000 km (Scania’s modular engine design reduces downtime).

- Tanker Lifespan: 15–20 years with proper care (aluminum resists rust better than steel).

7. Pricing & Lead Time

- Estimated Cost:

- Truck (R450 COBO): €120,000–€150,000 (new, depending on specs).

- ANOS Tanker Body: €80,000–€120,000 (6 compartments, aluminum).

- Lead Time: 6–12 months (custom builds require ANOS testing/certification).

Key Questions to Ask When Ordering:

- ADR Class Needed? (e.g., Class 3 for diesel/gasoline, Class 6.1 for additives).

- Local Weight Limits? (e.g., 36T vs. 44T GCW in Europe).

- Loading Type? (Bottom-load vs. top-load, vapor recovery compatibility).

- Climate Adaptations? (Insulated tanks for Arctic conditions).

1. Chassis & Powertrain (Extended Details)

- Engine (DC13 147):

- Euro 6 compliant (or regional equivalent, e.g., Euro V/EEV)

- SCR (Selective Catalytic Reduction) + EGR for emissions control

- Fuel efficiency features: Scania’s Eco Roll (coasting function) & predictive cruise control

- Transmission:

- Scania Opti cruise (12-speed automated gearbox) with Retarder or Exhaust Brake

- Optional: Scania GRSO926R (manual 12-speed) for heavy-duty operations

- Axle Options:

- 4×2: Common for lighter loads (~26–36T GCW)

- 6×4: Full traction for off-site refueling (e.g., mining/construction)

2. Tanker Body (ANOS Compliance & Safety)

- ANOS Certification (EN 13012):

- Mandatory in Europe for fuel tankers (ensures leak-proof design, crash resistance, and fire safety).

- Requires:

- Double-skin construction (outer shell protects inner tank)

- Overfill prevention system (90% auto-shutoff)

- Bottom-loading valves (reduces vapor emissions vs. top-loading)

- Compartmentalization:

- Typical 6-compartment layout (e.g., 3x 6,000L + 3x 4,000L for varied fuel types).

- Baffles: Anti-surge plates to stabilize liquid movement.

- Pump & Metering:

- Pump Types:

- Rotary gear pump (500–1,200 L/min flow rate)

- Optional: ATEX-certified for explosive environments

- Meter Accuracy: ±0.5% (legal trade requirement in most countries).

3. Operational Features

- Safety Systems:

- Static Grounding: Cable + interlock system to prevent sparks during loading/unloading.

- Emergency Shutoff: Remote-operated valves (via cab or wireless pendant).

- Ventilation: Pressure/vacuum relief valves for vapor control.

- ADR Compliance (Transporting Dangerous Goods):

- Class 3 (Flammable Liquids) – Requires:

- Orange hazard placards

- Fire extinguishers (2x 6kg powder)

- Driver ADR training certification

- Telematics & Tracking:

- Scania Fleet Management (real-time fuel monitoring, route optimization, theft prevention).

4. Customization Options

- Material Choices:

- Aluminum: Lightweight (~300–400kg lighter than steel), corrosion-resistant.

- Stainless Steel: For aggressive fuels (e.g., biodiesel, ethanol blends).

- Add-ons:

- Heated compartments (for cold climates to prevent fuel gelling).

- Vapor recovery system (environmental compliance).

- Rear-mounted hose reel (for direct refueling of equipment).

- Cab Options:

- Highline Cab: Sleeper berth for long-haul operations.

- Day Cab: For regional/short-haul deliveries.

5. Typical Use Cases

- Petrol Stations: Multi-compartment loads (e.g., diesel + gasoline + kerosene).

- Aviation Fuel: Dedicated stainless steel tanks for Jet-A1 (requires additional certifications).

- Industrial Sites: Off-road fuel delivery to mining/farming operations.

6. Maintenance & Lifespan

- Service Intervals: Every 60,000–90,000 km (Scania’s modular engine design reduces downtime).

- Tanker Lifespan: 15–20 years with proper care (aluminum resists rust better than steel).

7. Pricing & Lead Time

- Estimated Cost:

- Truck (R450 COBO): €120,000–€150,000 (new, depending on specs).

- ANOS Tanker Body: €80,000–€120,000 (6 compartments, aluminum).

- Lead Time: 6–12 months (custom builds require ANOS testing/certification).

- Key Questions to Ask When Ordering:

ADR Class Needed? (e.g., Class 3 for diesel/gasoline, Class 6.1 for additives). - Local Weight Limits? (e.g., 36T vs. 44T GCW in Europe).

- Loading Type? (Bottom-load vs. top-load, vapor recovery compatibility).

- Climate Adaptations? (Insulated tanks for Arctic conditions).

Advanced Tanker Structural Engineering

- A. Stress Analysis & Finite Element Modeling (FEM)

- Critical Stress Points:

- Bulkhead Welds: Fatigue cracks often initiate here due to cyclic pressure loading.

- Mounting Brackets: High stress at chassis-tanker interface (FEA-recommended reinforcement).

- Simulation Standards:

- EN 13094: Requires FEM for tanks >5,000L capacity under 0.5 bar pressure.

- Load Cases:

- Full Braking (0.8g deceleration) → Tests front bulkhead integrity.

B. Computational Fluid Dynamics (CFD) for Slosh Mitigation

- Simulation Parameters:

- Turbulence Model: k-ε (for high Reynolds number flow).

- Mesh Resolution: 5mm near baffles (critical for vortex prediction).

- Findings:

- Worst-Case Scenario: 50% fill + sudden stop → 12 k N surge force on rear bulkhead.

- Optimal Baffle Design: 30° angled perforations reduce slosh by 40% vs. flat baffles.

Get article on pdf file… Click now

…………Scania R450 COBO ANOS 6 Compartment Fuel Tanker………..