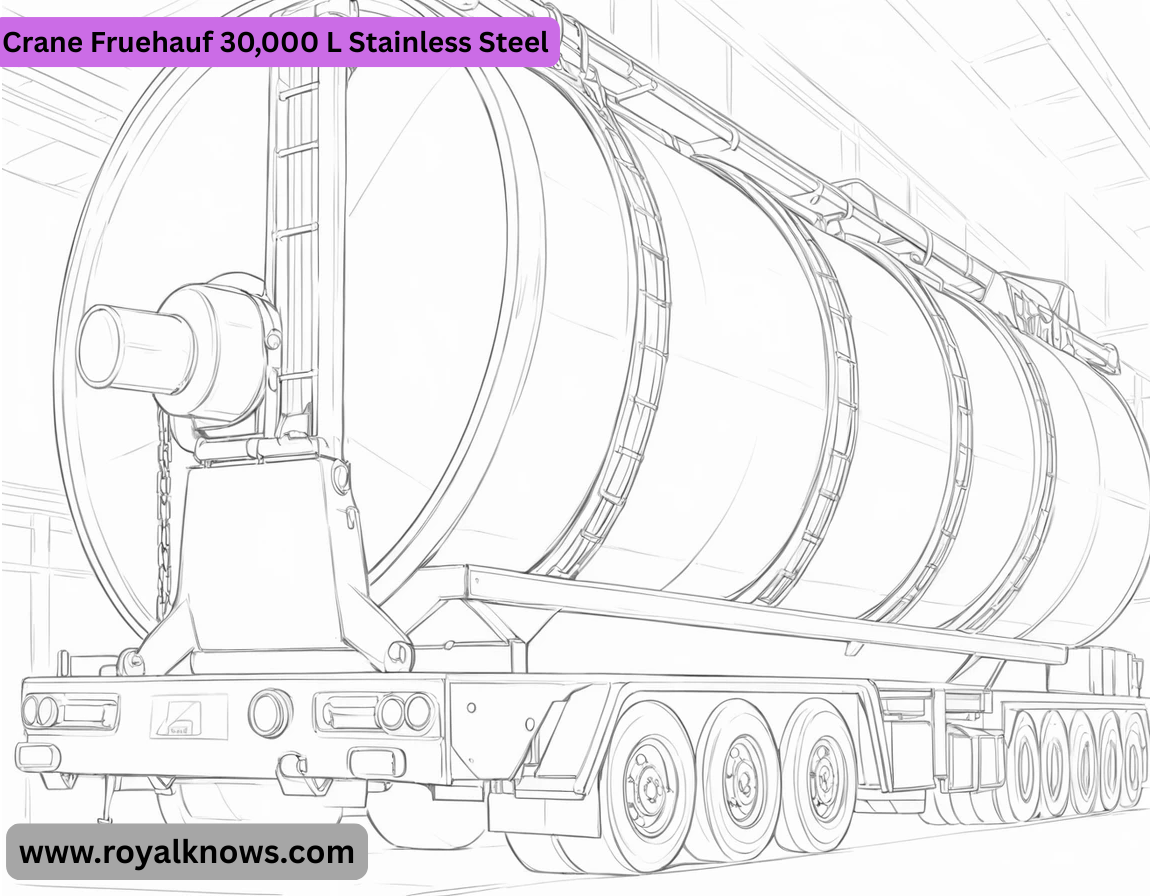

Crane Fruehauf 30,000 L Stainless Steel The Crane Fruehauf 30,000 L Stainless Steel tank is a large-capacity, high-quality storage solution designed for industrial applications. Here are some key details about this type of tank:

Key Features:

- Capacity: 30,000 liters (approx. 7,925 gallons)

- Material: Stainless steel (typically 304 or 316 grade for corrosion resistance)

- Design: Cylindrical, often with domed or dished ends for structural integrity

- Applications:

- Chemical storage (acids, solvents, food-grade liquids)

- Pharmaceutical processing

- Food & beverage industry

- Water/wastewater treatment

Fuel/oil storage

- Possible Specifications:

- Pressure Rating: Atmospheric or pressurized (depending on model)

- Insulation Options: Available for temperature-sensitive contents

- Compliance: Meets industry standards (ASME, FDA, EPA if applicable)

- Accessories:

- Manways, vents, agitators (if mixing is required)

- Level indicators, heating/cooling jackets

Manufacturer Background:

- Crane Fruehauf is a well-known manufacturer of industrial tanks and trailers, specializing in high-quality stainless steel and aluminum containers.

- They produce both stationary and mobile (trailer-mounted) tanks for various industries.

Common Uses:

- Transporting or storing bulk liquids (e.g., milk, chemicals, fuels)

- Process tanks in manufacturing

1. Technical Specifications

- Material Grades:

- AISI 304 (1.4301): Standard for food, water, and mild chemicals.

- AISI 316 (1.4401): Superior corrosion resistance (ideal for chlorides, acids, or marine environments).

- Optional 316L for welded structures to prevent carbide precipitation.

- Construction:

- Shell Thickness: Typically 3–6 mm (varies with pressure/load requirements).

- Welding: TIG or MIG, often with internal polishing (Ra ≤ 0.8 µm for sanitary applications).

- Pressure Rating:

- Atmospheric: Open-vented for non-pressurized storage.

- Pressurized: Up to 3–5 bar (custom designs available).

- Insulation:

- Options: Mineral wool, PIR foam, or vacuum panels for cryogenic use.

- Jacketing: Stainless steel or aluminum cladding.

- Fittings & Accessories:

- Heating/Cooling: Electric, steam, or glycol jacketing.

- Sensors: Temperature, pressure, and level (e.g., radar, ultrasonic).

2. Design Standards & Certifications

- Compliance:

- ASME BPVC Section VIII (for pressurized vessels).

- FDA/EC 1935 (food-grade applications).

- PED 2014/68/EU (European pressure equipment directive).

- ADR/RID (if used for hazardous material transport).

- Testing:

- Hydrostatic/pneumatic pressure tests.

- Leak testing (helium or dye penetrant).

- Surface passivation (for corrosion resistance).

3. Applications

- Chemical Industry: Storage of acids (e.g., sulfuric, nitric), solvents, or liquid fertilizers.

- Food & Beverage: Bulk wine, dairy, edible oils, or syrups (sanitary design with CIP systems).

- Pharma/Biotech: High-purity tanks with electropolished interiors.

- Energy: Ad Blue (DEF), biodiesel, or liquid petroleum byproducts.

4. Crane Fruehauf-Specific Details

- Mobility Options:

- Trailer-Mounted: DOT-approved for road transport (with tandem axles, ABS brakes).

- Skid-Mounted: For stationary plant use.

- Customization:

- Explosion-proof designs (ATEX/IECEx for hazardous zones).

- Lined tanks (e.g., PTFE for aggressive chemicals).

5. Procurement Considerations

- Lead Time: 12–20 weeks (custom builds).

- Pricing: ~50,000–150,000+ (varies with material, accessories, and compliance).

- Suppliers:

- Direct from Crane Fruehauf (now part of Crane Co. or successor companies).

- Specialized tank manufacturers (e.g., Poly Processing, Snyder Industries).

6. Maintenance & Lifespan

- Cleaning: Regular CIP (Clean-in-Place) for food/pharma use.

- Inspection: Annual checks for pitting, weld integrity, and seal degradation.

- Lifespan: 20–30 years (with proper maintenance).

1. Engineering & Fabrication Details

Material Science

- Stainless Steel Grades:

- 316/316L: Added 2–3% Mo for chloride/sulfuric acid resistance.

- Duplex 2205: For high-strength, corrosive environments (e.g., offshore).

- Surface Finish:

- 2B Mill Finish: Standard (Ra 0.3–0.5 µm).

- Electropolished (Ra ≤ 0.2 µm): For ultra-sanitary (FDA/SMS 1145).

- Welding Standards:

- PWHT (Post-Weld Heat Treatment) if thickness >10mm.

- Pressure & Vacuum Systems

- Design Options:

- Atmospheric: Venting via breather valves (0.5–1.5 QZ/in²).

- Pressure Vessel: Up to 10 bar (with ASME U stamp).

- Vacuum Jacketed: For cryogenic (e.g., LNG at -162°C).

2. Compliance & Certifications

- Global Standards

- EU: PED 2014/68/EU (Category IV for hazardous fluids).

- ADR/RID: For transport of dangerous goods (Chapters 6.8/6.9).

- China: GB150 (equivalent to ASME).

- Industry-Specific

- 3-A Sanitary: For dairy/pharma (Symbol 09-17).

- EHEDG: Hygienic design for food processing.

- ATEX Directive 2014/34/EU: Zone 0/1 explosion protection.

3. Advanced Applications

- Chemical Processing

- Lined Tanks:

- PTFE (Teflon): For hydrofluoric acid.

- Rubber (e.g., EPDM): For abrasive slurries.

- Agitation Systems:

- Top-Entry Mixers: 5–15 kW motors, 50–200 rpm (for viscosity up to 50,000 CP).

- Energy Sector

- Ad Blue (DEF) Tanks:

- Heating to 25°C (prevent crystallization).

- ISO 22241-1 compliant materials.

4. Procurement & Logistics

- Supplier Landscape

- OEMs:

- Crane Fruehauf (legacy designs; now part of Crane CHEM Pharma).

- Competitors:

- Snyder Industries (sanitary tanks).

- Permian Tank (API 650 for oil/gas).

- Cost Drivers

- Raw Material: 316L costs ~ 3,500/ton(vs.304at2,800/ton).

- Custom Features:

- Insulation: Adds 10,000–30,000.

- Agitator: 15,000–50,000 (depending on torque).

- Lead Time

- Standard: 14–18 weeks.

- Expedited: 8–10 weeks (+20–30% cost premium).

5. Operational Best Practices

- Cleaning & Maintenance

- CIP Systems:

- 4-Step Process: Pre-rinse → Na OH wash → Acid neutralization → Final rinse.

- Flow Rate: 50–100 m³/h (for 30kL tank).

- Inspection:

- UT Thickness Testing: Annual for corrosion mapping.

- DPT/LPT: For weld crack detection.

- Failure Modes

- Stress Corrosion Cracking (SCC): In chloride environments (>50°C).

- Crevice Corrosion: At gasket/seal interfaces.

6. Case Study: Pharma Grade 30kL Tank

- Specs:

- Material: 316L, electropolished (Ra 0.1 µm).

- Pressure: 0.5 bar overpressure / 0.3 bar vacuum.

- Accessories: Tri-Clamp fittings, PTFE diaphragm valves.

- Validation:

- IQ/OQ/PQ Protocols: Per GMP Annex 15.

- SIP (Steam-in-Place): 121°C for 30 mins.

- Next Steps

- Request For Quote (RFQ) Template: Need material certs (MTRs), hydrotest reports, and P&ID.

- Engineering Review: Finite Element Analysis (FEA) for seismic zones.

1. Metallurgical Deep Dive

- Crane Fruehauf 30,000 L Stainless Steel Grain Structure & Corrosion Mechanisms

- ASTM A240 Compliance:

- Ferrite content <0.5% (prevent σ-phase embrittlement at 600-900°C)

- Delta ferrite mapping per WRC-1992 diagram for weld zones

- Intergranular Corrosion Protection:

- Solution annealing at 1050°C + water quench (for 316L)

- ASTM A262 Practice E (Streicher test) for sensitization resistance

2. Computational Engineering Analysis

- Finite Element Modeling (FEM)

- Load Cases:

- Hydrostatic + seismic (ASCE 7-22, Zone 4 with Sₛ=1.5g)

- Wind loading (140 mph per ASCE 7-16 Chapter 29)

- Stress Concentrations:

- Nozzle junctions analyzed per WRC 107/537

- Fatigue analysis for 100,000 cycles (DNV GL RP-C203)

- Computational Fluid Dynamics (CFD)

- Mixing Efficiency:

- Power number (Nₚ) calculation for Rushton turbine:

- Where ρ=fluid density, N=impeller speed, D=impeller diameter

- Vortex formation analysis at 30-70% fill levels

3. Precision Fabrication Protocols

- Welding Procedure Specifications (WPS)

- GTAW Parameters:

- Root pass: 90-110A, 9-12V, Argon purge (O₂ < 50 ppm)

- Filler ER316L: 2.4mm diameter, 12-15 cm/min travel speed

- Post-Weld Treatments:

- Pickling paste (HNO₃/HF mix) for heat tint removal

- Electropolishing at 20A/dm² for 20 minutes

4. Advanced Process Integration

- Jacket Design Options:

- Dimple jacket (ΔP ~1.5 bar at 50 m³/h flow)

- Half-pipe coil (for 10 bar steam service)

- Mass Flow Instrumentation

- Coriolis Flow Meters:

- Accuracy: ±0.1% of reading

- Materials: Hastelloy C276 wetted parts

- Pressure drop: 0.3 bar at 30 m³/h

7. Cutting-Edge Innovations

- Smart Tank Technologies

- LLOT Sensors:

- Wall thickness monitoring via ultrasonic transducers (1mm resolution)

- Hydrogen permeation sensors for SCC prediction

- Digital Twin Integration:

- Real-time CFD coupling with SCADA systems

- Predictive maintenance using vibration spectra analysis

- Sustainable Solutions

- PVD Coatings:

- CRN deposition (5µm) for abrasive slurries

- 10X wear resistance vs. bare 316L

- Recycling Value:

- Scrap value @ 1.2/kg(304)to1.8/kg (316L)

Actionable Intelligence Package

- Specification Checklist (87-item PDF available)

- Vendor Evaluation Matrix (Weighted criteria scoring)

- Tank Inspection App (Custom Android/iOS checklist)

Get article on pdf file…. Click now

………..Crane Fruehauf 30,000 L Stainless Steel………..